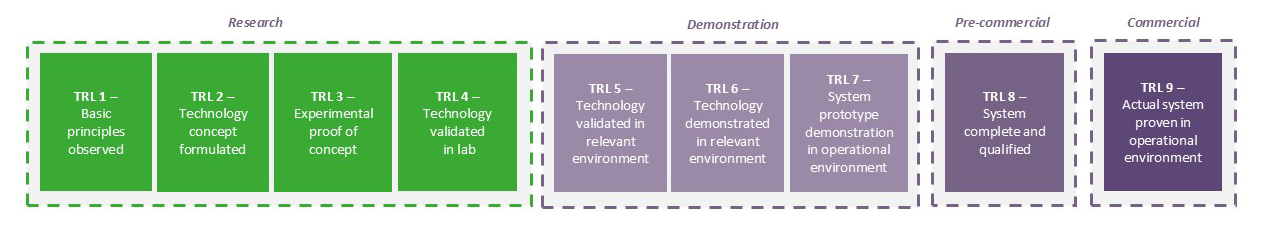

The Technology Readiness Level (TRL*) of research facilities plays a crucial role in assessing the maturity of technological developments. However, the TRL of a value chain is not determined solely by individual process steps but is also influenced by the type of feedstock used. Different feedstocks can introduce variability in process efficiency, scalability, and overall system performance, affecting the readiness and applicability of a given technology. Therefore, evaluating TRL requires a holistic approach that considers both technological advancements and feedstock compatibility within the value chain.

At the bottom of this page, you'll find a link to the Pyrolysis & Gasification Pathway Selector, where you can explore feedstock-technology combinations and view the TRL of the value chain along with explanations and existing demonstrations.

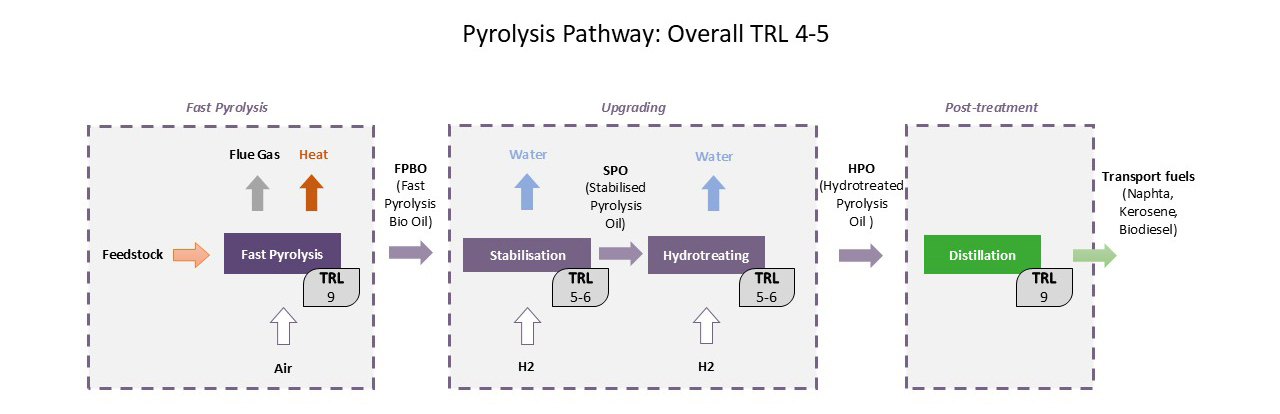

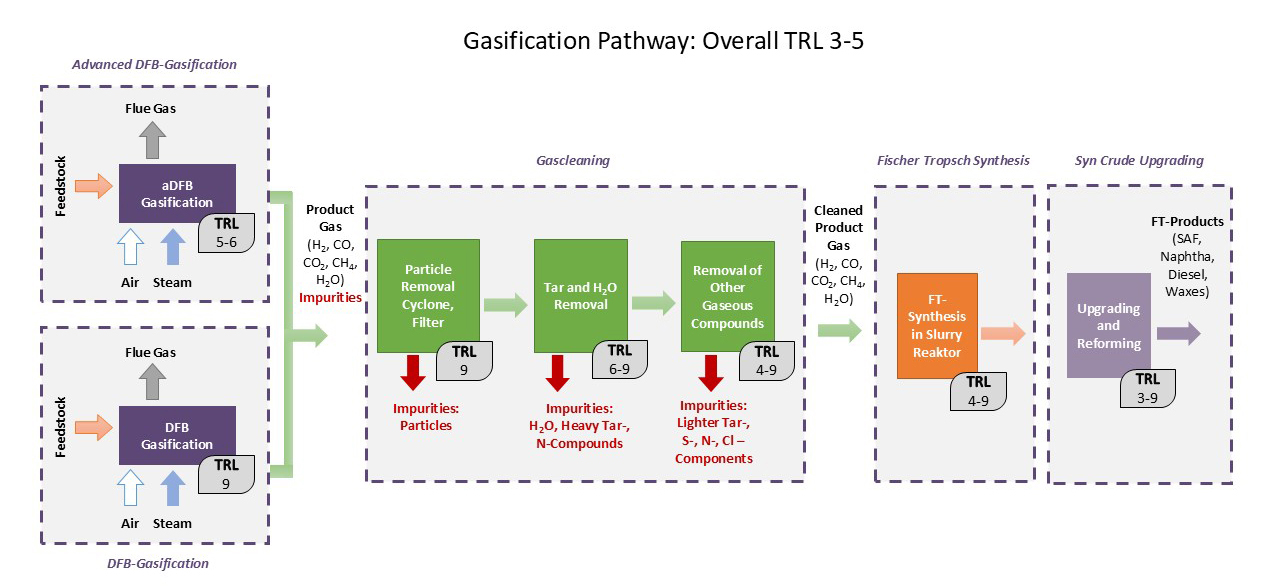

The BioTheRoS project is centered on two thermochemical pathways for advanced biofuel production: pyrolysis and gasification. Although these technologies have differences, they share core steps—converting biomass through the respective thermochemical technology followed by various upgrading processes to produce advanced biofuels. The Technology Readiness Levels (TRLs) vary across these individual process steps, and when combined with the choice of feedstock, they ultimately determine the overall TRL of the process. The TRLs of the process steps and the overall TRL are shown in the following flowsheets:

With pyrolysis, sustainable transport fuels can be produced from lignocellulosic biomass feedstock. The first step of the process – pyrolysis – is relatively simple and it is proven technology. The biomass is heated up rapidly in absence of oxygen and the resulting vapors are condensed to yield Fast Pyrolysis Bio Oil (FPBO). This is a liquid, which is easier to handle, store and utilize than regular solid biomass. To upgrade this FPBO to transport fuels, it is first stabilized in a high-pressure, catalytic process, using a proprietary catalyst (the Picula catalyst). After that, the stabilized pyrolysis oil is hydrotreated – using hydrogen - to yield a mix of transportation fuels. This mix can be separated into bio-naphta, SAF (Sustainable Aviation Fuel) and BioDiesel.

Dual fluidized bed steam gasification is an already commercially used thermochemical technology which produces a highly valuable product gas from woody biomass. The advanced version of this gasifier should be able to handle a wider variety of residual feedstocks and has been erected at a 1MW demonstration scale in 2022 at the Syngas Platform Vienna. For the downstream Fischer-Tropsch Synthesis application, an application dependent amount of gas cleaning has to be done, which reduces impurities like particles, tar components, as well as S-, N-, Cl- and other harmful components to a certain level to prevent unwanted reactions or catalyst poisoning. The FT Synthesis takes place in a slurry reactor, which is at a TRL 9 for big scales (>several 100 MW up to GW Scale), and now under development for small to medium scale Syngas application. After separation of the FT product biocrude, upgrading and reforming steps are performed to obtain the final products SAF, Naphtha, Diesel and Waxes.

*Definition of TRL we used in the BioTheRoS project: